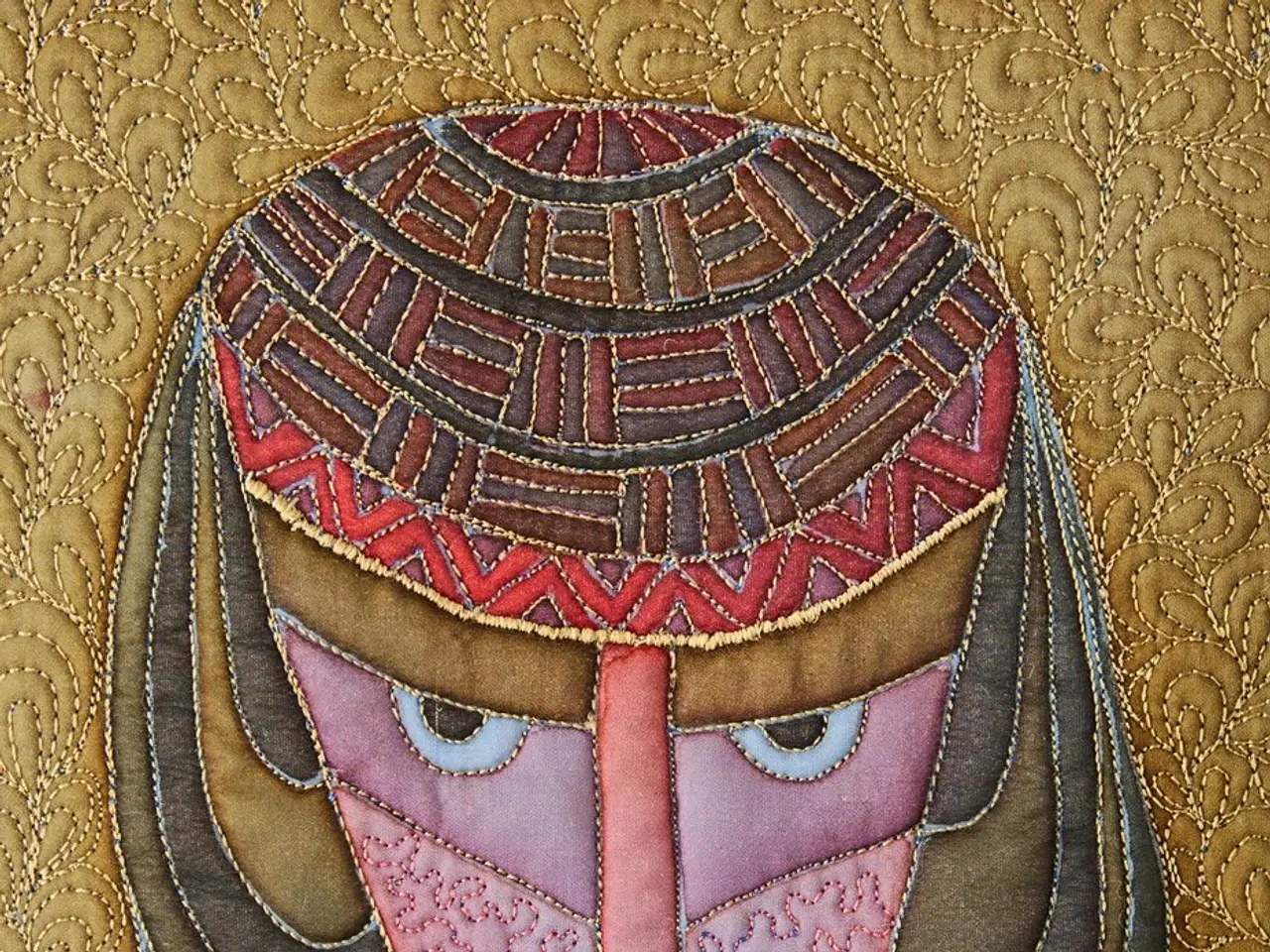

Advanced metal production platform for large-scale manufacturing

In the realm of advanced materials, a groundbreaking company named Foundation Alloy is making waves with its novel **solid-state metallurgy technology**. This technology, developed over many years at MIT and UC Irvine, enables the production of **ultra-high-performance metal alloys** without melting the raw materials during production.

At the heart of this innovation is the avoidance of traditional melting processes, which preserves and optimizes the metals' microstructure for better control over material properties and improved alloy strength. This solid-state approach results in alloys that are **twice as strong as traditional metals**.

One of the key advantages of Foundation Alloy's technology is its **advanced sintering method**, which uses pressure and heat but requires significantly less heat than traditional methods. This innovative process eliminates many secondary processing steps, saving time, reducing energy consumption, and lowering costs.

The company's technology also simplifies alloy design and manufacturing, allowing for **faster product development**. Companies can now test, iterate, and deploy new metal products up to 10 times faster than conventional methods, compressing the development timeline from years to months. This acceleration of innovation cycles could have a significant impact on industries dependent on advanced materials.

The versatility of Foundation Alloy's materials extends to traditional manufacturing methods such as metal injection molding, pressing, and 3D printing, facilitating adoption across various industrial applications without major retooling.

The resulting ultra-high-performance metals meet the stringent demands of fields like aerospace, defense, energy, and industrial tooling by providing materials that are not only stronger but also more reliable under extreme conditions. This breakthrough potentially removes failure points that arise from the physical constraints of conventional metals, enabling more robust and lightweight designs.

The company was founded by a team from MIT, including CEO Jake Guglin MBA '19, former MIT professor Chris Schuh, Jasper Lienhard '15, PhD '22, and Tim Rupert PhD '11. Guglin, inspired by a PhD student's thesis defense on a new way to create metal alloys, came to MIT's Sloan School of Management in 2017 to work with high-impact technologies.

Chris Schuh led the research that developed the company's solid-state metallurgy technology. Jasper Lienhard and Tim Rupert, who conducted their PhDs in Schuh's lab, invented complementary technologies to the solid-state processes developed by Schuh and his collaborators.

In 2022, Guglin and Schuh launched a company, adding Rupert and Lienhard, and licensing technology from MIT and UC Irvine. The company is currently piloting its metals across various industries and has received grants to develop parts for critical components of nuclear fusion reactors.

Foundation Alloy is designing and shipping demonstration parts to companies manufacturing components for various industries, including planes, bikes, cars, defense, and aerospace. With this technology, the company believes it can help businesses build higher-performing, more reliable systems, such as rockets, cars, nuclear fusion reactors, and artificial intelligence chips.

In conclusion, Foundation Alloy’s solid-state metallurgy technology revolutionizes metal alloy production by enabling stronger metals, rapid development, enhanced process control, and compatibility with existing manufacturing techniques. This innovation could significantly shorten product development timelines and improve industrial applications where advanced metals are critical.

- The groundbreaking company, Foundation Alloy, specializes in engineering solid-state metallurgy technology, which is responsible for producing ultra-high-performance metal alloys that are twice as strong as traditional metals.

- In a unique approach, Foundation Alloy's technology avoids traditional melting processes, maintaining the metals' microstructure for better control over material properties and improved alloy strength.

- One of the core advantages of Foundation Alloy's technology is its advanced sintering method, which uses pressure and heat but requires significantly less heat than traditional methods, saving energy, reducing costs, and streamlining the manufacturing process.

- The innovation simplifies alloy design and manufacturing, enabling companies to develop new metal products up to 10 times faster than conventional methods, potentially compressing the development timeline from years to months.

- The versatility of Foundation Alloy's materials extends to traditional manufacturing methods, such as metal injection molding, pressing, and 3D printing, facilitating adoption across various industrial applications without major retooling.

- These ultra-high-performance metals meet the stringent demands of industries like aerospace, defense, energy, and industrial tooling, providing materials that are not only stronger but also more reliable under extreme conditions.

- The breakthrough potentially removes failure points that arise from the physical constraints of conventional metals, enabling more robust and lightweight designs.

- The company, led by MIT alumni and faculty, aims to help businesses build higher-performing, more reliable systems in industries such as planes, bikes, cars, defense, aerospace, and more.

- In the realm of science and technology, Foundation Alloy's solid-state metallurgy technology could have a significant impact on industries dependent on advanced materials, driving breakthroughs in energy, finance, nuclear fusion, space, aerospace, and technology.