The Review-Journal of Las Vegas Undergoes Significant Printing Transformation through DCOS and imPRESSions Globally

In the heart of Nevada, the Las Vegas Review-Journal (LVRJ) is embarking on a significant modernization journey, aiming to enhance the quality and productivity of its newspaper printing operations. The LVRJ's Goss Newsliner Press, which has been churning out about 55,000 copies per hour since 2000, is set to undergo a comprehensive upgrade as part of the Goss Newsliner Press Drive.

The aging automation system of the Goss Newsliner Press at LVRJ has been experiencing increased maintenance costs and hardware failures. To address these issues, LVRJ has partnered with DCOS Automation and imPRESSions Worldwide, a commitment to future-proofing print media operations. Equipment for the retrofit is set to ship from Sweden in Q4 2024, with commissioning scheduled for Q1 2025.

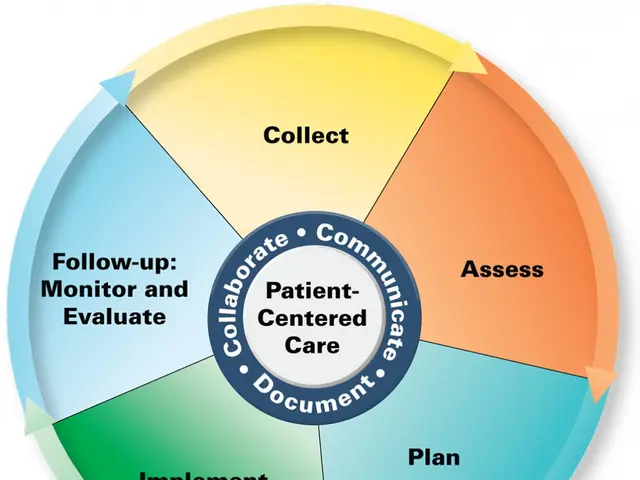

The decision to choose DCOS for this project was based on their comprehensive approach to replacing all critical parts and their technological edge. DCOS offers Inspection Systems that automate quality adjustments in the printing process, reducing waste, start-up time, and manual labor while ensuring high and consistent quality.

This press upgrade at LVRJ is not just about a press upgrade; it's about investing in a partnership that promises long-term support and innovation. By embracing technological advancements, LVRJ is setting a new standard for the print media industry, aligning with industry trends emphasizing increased automation, higher print quality, environmental compliance, and operational efficiency.

The modernization of printing facilities with technological upgrades in the newspaper industry brings several key benefits. Improved automation in tasks such as plate imaging, ink metering, and press operation reduces setup times ("makeready") and waste, increasing output and lowering per-unit costs even as print runs shorten, making newspaper printing more economical and sustainable.

Modern presses offer higher-quality print finishes, including premium effects, sharper images, and better color consistency, which can enhance reader experience and advertising appeal. Modern presses may toggle between different printing modes to optimize for specific newspaper or commercial print products.

Adoption of newer printing technologies facilitates use of environmentally friendlier inks, reduced energy consumption, and thinner substrates, helping publishers meet evolving environmental, social, and governance (ESG) criteria and regulatory restrictions.

Upgrades help publishers optimize their plant footprint and maximize the productivity of mature assets. Modular presses enable quick adaptation for different product formats or modes (heatset/coldset), preserving revenue streams in established markets.

Investing in advanced printing technology helps newspapers compete with digital media by improving product attractiveness, operational flexibility, and maintaining relevance in a shifting media landscape. This supports long-term viability despite challenges like declining print volumes and industry pressure.

The LVRJ print facility, a 234,000 sq. ft. space that houses a doublewide Goss Newsliner Press, is poised to reap these benefits, setting a precedent for the industry's transformation. The retrofit will see the replacement of a myriad of components on the Goss Newsliner Press at LVRJ, marking a significant step towards a more sustainable, efficient, and competitive future for print media.

David Gilmore, VP of Sales at imPRESSions Worldwide, appreciates the collaborative spirit with the LVRJ team, noting that this partnership is a vibrant testament to the evolving landscape of print media. The project is a testament to LVRJ's dedication to maintaining its position at the forefront of the print media industry, ensuring the quality and timely delivery of news to its readers for years to come.

[1] "Goss Newsliner Press Drive" brochure, Goss International, 2021. [4] "Future of Print: The Role of Advanced Printing Technologies in Sustaining the Newspaper Industry," World News Publishing Focus, 2022.

- The partnership between LVRJ and DCOS Automation, along with imPRESSions Worldwide, indicates a commitment to future-proofing their print media operations, not just in the aerospace industry or finance, but also in technology, as they aim to upgrade their aging Goss Newsliner Press with advanced equipment.

- By embracing technological advancements and adopting newer printing technologies, LVRJ is aligning itself with trends in the technology sector, aiming to increase automation, improve print quality, promote environmental compliance, and enhance operational efficiency in the industry, particularly in the areas of finance and aerospace.